In recent years, many compressor manufacturers have intensified their engagement in the hydrogen sector. Several medium-sized companies entered into new partnerships, and there have been several corporate takeovers. And individually dealing with compressors is no longer a separate ordeal for many, but is now offered in package with other services that are also needed for the development of a hydrogen infrastructure. But what distinguishes the different manufacturers and various products from each other? H2-international asked manufacturers about technologies, trends and special features, and has gathered the results here – with no claim of completeness.

Without compressors, hydrogen technology could not go anywhere. In order for H2 gas to be stored and transported, it is necessary to press as many of these little molecules as possible into gas cylinders, cavities or car tanks, to produce the highest possible energy density. This is more difficult with hydrogen than with other gases, since the tiny molecules can escape through the smallest crevice. At the same time, sealing materials can be potential sources of contamination of the hydrogen.

Compressors differ in both their compression and drive technology. The driver could be, for example, compressed air, hydraulics or an electric motor. Which compression method is right depends, among other things, on the required throughput, the pressure level and the purity needed.

An essential aspect is the initial pressure, so the inlet pressure, for the compressor. If the hydrogen is taken, for example, from a gas container in which the pressure is low or only atmospheric, much more compression work is required than, for example, when already pre-compressed up to 100 bar from an upstream electrolyzer. Since the energy required to compress gases is very high, it may be more economic to apply 30 bar to the feed water at the input side of the electrolyzer than to compress the hydrogen downstream.

Market overview

H2-international has asked manufacturers of compressors for hydrogen fueling stations about their products, innovations and trends. We did not create a tabular market overview, like that for the electrolyzers in the February 2022 issue of H2-international, as the technical specifications given for different compressors are already too different in nature and there are no uniform standardized conditions for measuring inlet and discharge pressure. But the main features are summarized in this article. If the manufacturer has given us specifications about their product, this information is featured in a profile and sorted under the appropriate parameters. Included were H2 compressors for fueling stations at which the output pressures generally amounted to 350 or 700 bar.

Reciprocating compressors

Piston compressors are the classics known from engine technology They are robust and can deliver high pressures and medium to high throughputs (starting from about 4 tonnes per day). Gasoline and diesel engines of common vehicles are lubricated with oil. Even with oil scraping rings, there is always a thin film of oil remaining on the walls of the combustion chambers, which is desirable to reduce friction. In piston compressors of hydrogen vehicles, this is not desirable, as this oil contaminates the medium to be compressed. A downstream fuel cell in which this gas is destined for use would be contaminated and fail after a short time. For this reason, oil-lubricated piston compressors can only be used in hydrogen systems in combination with subsequent purification of the gas.

Such cleaning can be done with scrubbers based on activated carbon. One of the providers of this technology is Bauer Kompressoren GmbH. The Bavarians started 15 years ago with a, by today’s standards, small H2 project in Spain. The production rate was 35 m3 per hour with up to 350 bar. In addition to activated carbon, the Munich-based company used a molecular sieve, which allowed it to provide hydrogen in 3.7 to 5.0 purity grade (?99.97{7bfcd0aebedba9ec56d5615176ab7cebc5409dfb82345290162ba6c44abf8bc8} to ?99.999{7bfcd0aebedba9ec56d5615176ab7cebc5409dfb82345290162ba6c44abf8bc8}). Bauer has been active in the high-pressure sector for 77 years, for example with diving cylinders.

With its H450 compressor, Borsig GmbH manufactures piston compressors for truck fueling stations. A special feature, according to the manufacturer, is the gas seal in the last compression stage. In addition, this compressor can be operated safely even under tough environmental conditions, it was said.

| Manufacturer | Borsig GmbH |

| Name of compressor | H450 |

| Compressor type | Reciprocating (without fueling station) |

| Pressure classes | 350 bar |

| H2 capacity | 275 kg/h |

| Input power (el) | 375 kW |

| Dimensions (L x W x H) | 3.4 x 1.3 x 0.8 m |

| Energy requirement | 1.3 kWh/kgH2 (40 bar input pressure, 450 bar output pressure) |

Sauer Compressors as well is positioned in the medium power range and offers oil-lubricated piston compressors with downstream treatment. The family-run compressor manufacturer headquartered in Kiel, Germany touts robustness as the foremost advantage of this technology. The piston compressors can handle variation of the load as well as fluctuating temperatures. This makes these compressors interesting for use in microgrids and other applications that require a high degree of self-dependence. In addition, according to information by the manufacturer, they are easy to repair. One unique thing about Sauer is that the customers are trained so that they can maintain and repair the compressors themselves – and may do so without voiding the warranty.

To Sauer also belongs the St. Gallen, Switzerland-based company Haug Sauer Kompressoren AG, which manufactures smaller, oil-free compressors. The dry-running units from Haug can deliver up to 1,000 m3 per hour. The model HAUG.Mercure 22E presented at H2Expo, for example, compresses 7 to 13 m3H2/h from up to 24 bar to a maximum of 350 bar.

Dry-running compressors use, for example, PTFE piston rings as an alternative to oil lubrication in the cylinder. The rings are offered by, among others, ElringKlinger and are quite low-wear, but leave traces of abraded material in the compressed medium, which must then be removed with particle filters. Some of these compressors use an oil pan at the bottom of the crankcase for lubrication. However, in these cases, this area is separated from the compression space by a three-stage sealing system so that no impurities emerge there. Oil-free piston compressors can typically be used for pressures from 150 to 450 bar; some at higher pressures as well.

In 2022, together with Bosch Rexroth, Maximator Hydrogen GmbH presented the new compressing unit MAX Compression 2.0 (see H2-international August 2022). This has up to five times the throughput of its predecessor, within the same construction volume. The energy requirement was also minimized by the providers, according to the press release. The highlight is that although compression still takes place in two stages, the hydrogen no longer needs to be stored between these stages. In the 75-kW class, the throughput should increase by 20 percent at the same driving power, which should decrease costs accordingly. The power classes additionally range from 75 to 250 kW. This allows the capacity of a hydrogen fueling station to be increased if necessary without major reconstruction.

A special feature is the automatic changing out of the seals (automatic seal exchange, ASX). The bar loader used for this purpose can hold up to 20 interchangeable seals. Per seal, it takes about 15 seconds for the exchange, so seal replacement for the whole system should be complete within three minutes.

In November 2022, the company from Nordhausen reported reception of a major order from Sweden. From autumn 2023 to the end of 2025, Maximator is to provide compressors for the in total 24 hydrogen fueling stations that are to arise in the course of the project REH2. These are to supply primarily heavy trucks, and 23 of the 24 are planned to be installed at highway rest stations. REH2 wants to supply exclusively green hydrogen that is produced primarily with local energy sources such as wind and water. Majority owner of the project is the investment company Qarlbo AB.

The FSS High Capacity Station from the company Resato is a modular system. The number of compressors and dispensers can be varied to suit demand. Thus, a high production capacity is possible by joining the standardized components, which are available in the modular sizes for 1,000 or for 2,000 kgH2/day. The hydrogen can be supplied by tube trailers or multiple element gas containers (MEGCs) coming directly from an electrolyzer or from the pipeline. The available hydrogen quantity, according to Resato, sets the limit for the capacity of the fueling station.

According to Resato, the fueling stations are user-friendly, reliable and have a favorable marginal cost. In addition, the supplier has a Europe-wide network for after-sales support.

| Manufacturer | Resato |

| Name of compressor | FSS – High Capacity Station |

| Compressor type | Electrohydraulic piston compressor and fueling station system |

| Pressure classes | 350 bar, 700 bar |

| H2 capacity | >1,000 kg/day, >2,000 kg/day |

| Input power (el) | 185 kW |

| Base area | 10 m x 12 m (without hydrogen provision) |

Diaphragm compressors

Membrane compressors are suited for higher pressures up to 1,000 bar. They too essentially use a piston to compress gas. However, this does not act directly on the gas, but on an oil, which in turn moves a membrane. The gas to be compressed is enclosed by this membrane (diaphragm). This way, neither hydrogen gets out nor contaminants get in. Membrane compressors are therefore free of contamination and have no loss from leakage. They are suitable for frequent or continuous operation. However, they are technically limited to H2 throughputs on the order of 1 to 2 tonnes per day. This makes them less of interest for hydrogen truck fueling stations, for example.

Andreas Hofer Hochdrucktechnik GmbH, which belongs to Neuman & Esser (NEA Group), according to its own statement, can guarantee pressures of 5,000 bar with diaphragm compressors and up to 3,000 bar for dry-running, hydraulically driven piston compressors.

The MD10-L membrane compressor from Burckhardt Compression is available as a standardized mobile container-installed solution or as a bare unit. It can also be supplied with noise reduction and a closed cooling water system, if needed. The size is adapted to a 2.5-MW electrolysis unit. The membrane compressor ensures high hydrogen purity and gas tightness. For higher throughputs, Burckhardt Compression recommends its own 3CS oil-free piston compressor. According to the company, it supplied its first hydrogen compressor as early as 1972. The manufacturer has a service network that reaches around the world and offers a comprehensive after-sales service.

| Manufacturer | Burckhardt Compression |

| Name of compressor | MD10-L |

| Compressor type | Diaphragm compressor |

| Pressure classes | 350 bar |

| H2 capacity | 45 kg/h |

| Input power (el) | 81 kW (rated power at specifications given below) |

| Energy requirement | Approx. 1.8 kWh/kgH2 (30 bar input pressure, 550 bar output pressure, 45 kg H2/hour) |

| Dimensions (L x W x H) | 6.1 m x 2.44 m x 2.59 m |

Centrifugal and screw rotary compressors

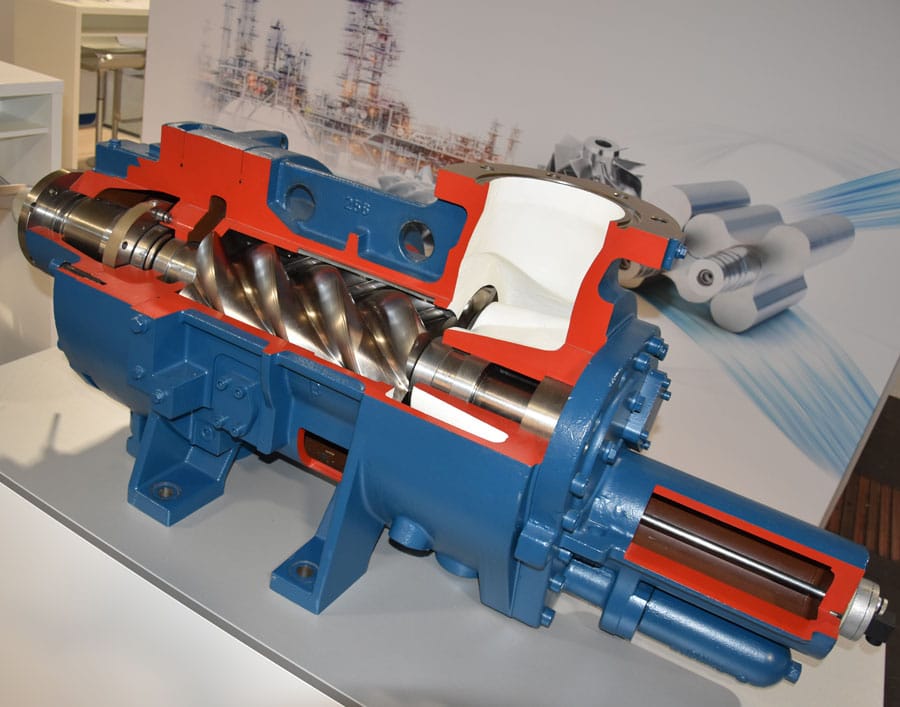

For lower pressure levels, centrifugal (turbo) compressors and screw compressors are the go-tos. Their typical pressure range lies at about 1 to 20 bar, and the throughput at up to 50,000 m3H2 per hour. For hydrogen fueling stations, they can therefore only serve in the pre-compression stage, to build up the ingoing pressure required for the other compressor types. The operating principle of a screw compressor is two interthreading screw rotors rotating inwards of each other (see Fig. 1).

In this way, the volume to be acted on is increasingly reduced. Similarly to the case with piston compressors, a pulsation accordingly arises in dependence on the rotational speed of the screw, which could be 1,500 to 2,000 rpm for large units and up to 5,000 rpm for small units. In general, screw compressors have a higher leakage rate compared to other compressor types and thus higher efficiency losses. To reduce friction and improve tightness, oil is used similarly to the use for piston compressors.

One manufacturer of screw compressors is Aerzener Maschinenfabrik GmbH. A new innovation by the engineering company is the substitution of oil with water. The water film seals similarly well to oil, prevents contamination and, at the same time, leads to a thoroughly desired humidification of the H2 gas. This method, however, is still in the testing phase.

In addition to this, there are ionic compressors, such as those manufactured by Linde.

Manufacturers, business models and trends

Some of the companies listed here are primarily focused on the manufacture of compressors. Others, on the other hand, see their area of business as turnkey hydrogen fueling stations. Especially amongst the makers specializing in compressors are family-owned companies steeped in the technological tradition of the German-speaking area. A prime example and, by its own statement, the world market leader for reciprocating compressors is Burckhardt Compression AG from Winterthur, Switzerland, with now 2,700 employees.

According to the company, Burckhardt Compression works on membrane as well as piston compressors that can deliver pressures of over 900 bar and additionally are suitable for high throughput volumes. The company, which has been listed on the stock exchange since 2006, shows – not only in the H2 sector – a clear willingness to grow globally, as evidenced by recent acquisitions: Industrie- und Kompressorenservice GmbH from Bremen (2016); CSM Compressor Supplies & Machine Work Ltd from Canada (2017); Arkos Field Services from the USA (2019); The Japan Steel Works Ltd from the USA (2020); Shenyang Yuanda Compressor Manufacturing Co, Ltd from China (2021).

In the hydrogen sector, the company founded in 1844 is engaged not only in H2 station and trailer refueling solutions, but also power-to-gas projects and offshore H2 production. In spring 2022, Burckhardt Compression began construction of its very own H2 testing facility at its headquarters in Winterthur. There, the company intends to further develop sealing technologies for heavy hydrogen commercial vehicle fueling stations that would allow oil-free compression up to 900 bar (as booster). The goal is to get in business with Shell New Energies. Burckhardt Compression says it’s one of the finalists in the race for the energy giant’s fueling station business. The testing facility is to go into operation in early 2023, and the tests should be completed by the end of the year.

In 2022, Burckhardt Compression entered into a partnership with the H2 fueling station developer HRS (formerly TSM). This involves the delivery of several membrane compressors within the next two years for the fueling stations of HRS, the capacity of each of which is to be between one and two tonnes per day. The target group for these fueling stations is heavy transport (buses, trucks, port vehicles) and light commercial vehicles, like taxi fleets. With the partnership, the two companies want to equip other areas of hydrogen mobility already as well, such as ships, trains and planes.

The Neuman & Esser Group (NEA) as well is a heavyweight in the compressor sector. The family business from Übach-Palenberg, with its 1,200 employees, is making a name for itself through, among other things, the two managing partners, as Stefanie and Alexander Peters are both strongly engaged in lobby associations as well as on the political administration level. Stefanie Peters is active in the German hydrogen council (Nationaler Wasserstoffrat, NWR), among other things, while her brother is director of the compressor and vacuum division within the German association for mechanical engineers (Verband Deutscher Maschinen- und Anlagenbau, VDMA). In addition, at the beginning of December 2022, he was voted to become an executive director of the German hydrogen and fuel cell association (Deutscher Wasserstoff- und Brennstoffzellen-Verband, DWV).

PDC Machines from Pennsylvania is, by its own statement, the world’s leading manufacturer of diaphragm compressors for hydrogen. H2 applications are the second mainstay of the US company alongside classic industrial compressors. In addition to the compressors, the portfolio includes a complete mini refueling unit named SimpleFuel as well as turnkey hydrogen refueling stations.

In 2022, PDC Machines announced a cooperation with US supplier Gilbarco Veeder-Root. The company plans to establish an end-to-end infrastructure for refueling that in addition to the compressors from PDC machines and the dispensing stations, also encompasses the necessary software for operation. This is to occur via the wholly owned subsidiary ANGI Energy Systems, which is responsible for Gilbarco’s compressed gas business and has already been developing complete solutions for its customers for 30 years.

PDC Machines is currently benefiting, like many US companies, from the US Inflation Reduction Act. Among other things, this provides for a ten-year tax bonus for clean hydrogen and H2 storage systems. In addition, there are to be tax advantages for fuel cell vehicles and better tax credits for “clean fueling stations.”

Hiperbaric, headquartered in Burgos, Spain, has been active in H2 compression since 2021. The company started in 1999 with solutions for the food industry. In the hydrogen sector, Hiperbaric has devoted itself to compressor units preinstalled in portable packages for use at filling stations and research facilities or for gas storage. In addition to the high-pressure piston compressors themselves, the containerized solutions contain the controls, cooling, ventilation and the pneumatic and hydraulic systems. The compression takes place in two stages.

The compressor unit is available in options for up to 500 or up to 950 bar. The 500-bar unit has a throughput of up to 26 kg of hydrogen per hour, and the 950-bar unit up to 15 kg per hour. With a second compressor installed in the container, the rate can be doubled. The offer includes a complete service, with maintenance. The remote monitoring and diagnostics service should ensure that errors are detected before a failure in the system occurs.

Compressor trends

The question of how to offer more and larger compression and refueling station solutions for hydrogen as easily as possible is on the minds of all manufacturers. Borsig names standardization and scaling as the keys to reducing costs. Resato sees itself well prepared for capacity expansions with the modular approach. The company wants to think less in terms of individual projects in the future and instead turn hydrogen fueling stations into a “business tool.” Instead of a single fueling station optimized for low investment and operating costs, customers should receive a complete product with business model included. The decisive optimization variables here are reliability and the question of what it costs to put one kilogram of hydrogen into the tank of a vehicle.

Authors: Eva Augsten, Sven Geitmann

Image: Bolts Schrauben-DSC_0277-Ausschnitt