Lyten’s lithium-sulfur batteries to be tested on ISS

by Clarence Oxford

Los Angeles CA (SPX) Sep 18, 2024

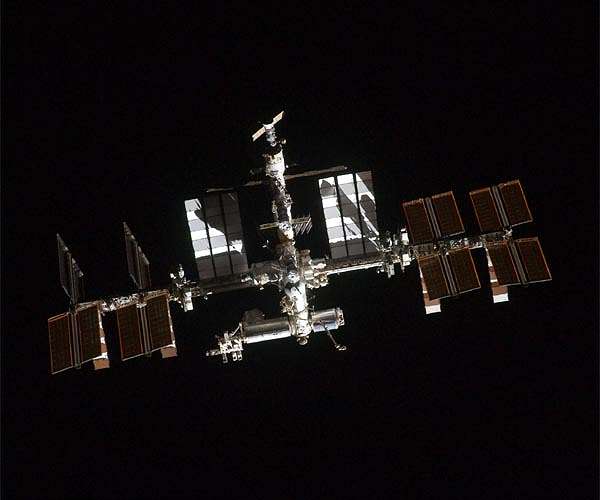

Lyten, a leader in supermaterial applications and lithium-sulfur battery technology, has announced that its rechargeable lithium-sulfur battery cells have been selected for testing aboard the International Space Station (ISS). The Department of Defense’s Defense Innovation Unit (DIU) is funding this project as part of its ongoing collaboration with Lyten, focused on lithium-sulfur battery development and production.

As part of this agreement, DIU is funding the integration and testing of Lyten’s rechargeable lithium-sulfur cells by Spacebilt/Skycorp. The batteries will undergo rigorous tests under launch, orbital, and recovery conditions, aimed at assessing their viability for use in satellites, space suits, and extravehicular activities, among other applications. Lyten aims to achieve flight certification for its cells, confirming their compatibility with space environments and opening the door for use in a variety of space missions.

“The process for inclusion of batteries for testing on the International Space Station is a highly competitive one and a necessary step to enable broad adoption of lithium-sulfur for space applications. We are honored by the selection of Lyten’s lithium-sulfur cells,” said Dan Cook, Lyten Co-Founder and CEO. “We believe the high gravimetric energy density and light weight of our lithium-sulfur cells make them a perfect fit for current and future space applications.”

The testing will be carried out on the ISS under the sponsorship of the ISS National Lab and will be part of a NASA-funded commercial resupply mission. Lyten plans to qualify three different battery cell formats, including pouch cells and two sizes of cylindrical cells, during the ISS testing.

“The rapid growth in low earth orbit satellite deployments in support of communications and the expansion of the broader space economy create a very compelling use for high-energy density, lithium-sulfur battery cells. These are applications where weight and reliability are of critical importance,” said Celina Mikolajczak, Lyten Chief Battery Technology Officer.

Ratnakumar Bugga, Senior Fellow at Lyten with over 34 years of experience in space battery research and development, added, “Lithium-sulfur battery technology development was originally funded by NASA to extend Astronaut’s extravehicular activity to 8 hours versus the 4 – 5 hours possible with existing lithium-ion batteries. Lyten now has the opportunity to validate this technology on the ISS.”

Lyten recently partnered with AEVEX to demonstrate unmanned air vehicles (UAVs) powered by its lithium-sulfur batteries, marking the first aerospace application for this technology. These high-energy-density cells can reduce weight by up to 40% compared to lithium-ion batteries and 60% compared to lithium iron phosphate (LFP) batteries, making them highly suitable for industries such as automotive, space, aerospace, UAVs, micromobility, defense, and consumer electronics.

Lyten’s lithium-sulfur batteries are manufactured in San Jose, CA, in both pouch and cylindrical formats. The cells are made using locally sourced materials and are fully manufactured in the United States, ensuring compliance with the Inflation Reduction Act and the 2024 National Defense Appropriations Act, while avoiding tariffs on materials imported from China.

Earlier this year, Lyten was recognized by Fast Company as the #8 most innovative energy company in the world, and for the second consecutive year, was listed on the Silicon Valley Defense Group’s NATSEC100 as the only battery company recognized for its national security technologies.

Related Links

Lyten

Powering The World in the 21st Century at Energy-Daily.com