World’s strongest battery could enable lightweight, energy-efficient vehicles

by Robert Schreiber

Berlin, Germany (SPX) Sep 15, 2024

Building vehicles or electronics with materials that serve as both batteries and structural components could significantly reduce weight and energy consumption. A research group at Chalmers University of Technology, Sweden, has introduced a significant development in massless energy storage. Their newly developed structural battery has the potential to cut the weight of devices like laptops by half, make mobile phones as thin as credit cards, and extend the driving range of electric cars by up to 70% on a single charge.

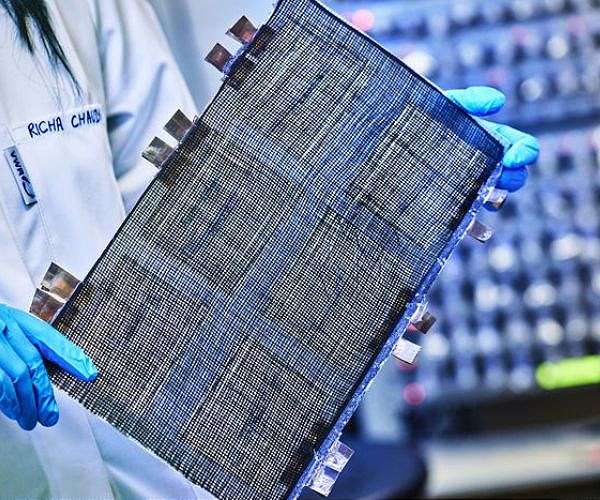

“We have succeeded in creating a battery made of carbon fibre composite that is as stiff as aluminium and energy-dense enough to be used commercially. Just like a human skeleton, the battery has several functions at the same time,” explained Richa Chaudhary, a researcher at Chalmers and the lead author of a scientific article published in ‘Advanced Materials’.

Research into structural batteries has been ongoing for several years at Chalmers, sometimes in collaboration with researchers at KTH Royal Institute of Technology in Stockholm. The breakthrough came in 2018 when Professor Leif Asp and his colleagues demonstrated how stiff, strong carbon fibres could store electrical energy chemically, attracting global attention. The discovery that carbon fibre can serve as electrodes in lithium-ion batteries was one of the top 10 scientific achievements of the year, according to ‘Physics World’.

Less weight, more efficiency

Since 2018, the research team has made strides in enhancing both stiffness and energy density. In 2021, they reached a key milestone with a battery offering 24 watt-hours per kilogram (Wh/kg), equivalent to about 20% of the capacity of a typical lithium-ion battery. Today, they have improved this figure to 30 Wh/kg. While still below current commercial batteries, the benefits of weight reduction create a new dynamic. With the battery forming part of the vehicle’s structure, less energy is needed overall.

“Investing in light and energy-efficient vehicles is a matter of course if we are to economise on energy and think about future generations. We have made calculations on electric cars that show that they could drive for up to 70 percent longer than today if they had competitive structural batteries,” said Leif Asp, a professor in the Department of Industrial and Materials Science at Chalmers.

For vehicles, strength is paramount to meet safety standards. The structural battery developed by the team has significantly increased stiffness, raising the elastic modulus from 25 to 70 gigapascal (GPa). This means the material can bear loads as effectively as aluminium while being much lighter.

“In terms of multifunctional properties, the new battery is twice as good as its predecessor – and actually the best ever made in the world,” commented Asp, who has been involved in structural battery research since 2007.

Progress towards commercialisation

The ultimate goal from the outset has been to achieve performance levels suitable for commercialisation. With ongoing research, there are now stronger ties to the market through the establishment of Sinonus AB, a Chalmers Venture company located in Boras, Sweden.

Despite the progress, more engineering work is necessary to scale up production from small lab batches to the large-scale manufacturing needed for consumer electronics or vehicles.

“One can imagine that credit card-thin mobile phones or laptops that weigh half as much as today, are the closest in time. It could also be that components such as electronics in cars or planes are powered by structural batteries. It will require large investments to meet the transport industry’s challenging energy needs, but this is also where the technology could make the most difference,” says Leif Asp.

Research Report:Unveiling the Multifunctional Carbon Fibre Structural Battery

Related Links

Chalmers University of Technology

Powering The World in the 21st Century at Energy-Daily.com