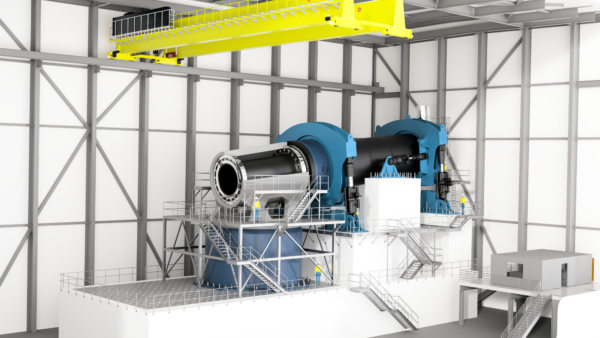

Denmark-based R&D Test Systems is building what it calls the most powerful test bench for wind turbine main bearings, as the industry needs to test larger components for the expected giant wind turbines of the future.

The company has completed the 3,700 metric ton foundation and is now designing and welding the test bench parts that will perform test loads on main bearings for 25 MW wind turbines. With delivery set for next year, the test bench is bound for LORC’s new main bearing test facility.

LORC is the owner of the new main bearing test facility, also set to be delivered next year. It contracted R&D Test Systems to build the test bench for main bearings at Odense Port, Lindø, Denmark.

“It’s in recognition of our large-scale testing capability that LORC has selected R&D Test Systems to build the most powerful test bench for main bearing arrangements,” says Peter Winther, key account manager, R&D Test Systems.

“The foundation is complete, and our engineers have designed the systems that will apply the actual loads to simulate not only the harshest forces of wind but also the effect of wind coming from different directions.”

Critical to ensuring the turbine operates smoothly and efficiently, the main bearing supports the main shaft, keeping it stable and properly aligned, the company adds. It also transfers the loads caused by the rotor blades to the turbine structure and allows generated torque to transfer to the gearbox and generator. To test and validate large main bearings, the new test bench will apply loads that simulate real-life wind conditions in an accelerated manner.

With a length of 35 meters and a height of 18 meters, the test bench will be the longest of any of the LORC’s test bench facilities at Odense Harbor in Denmark.

The project received a €10 million grant from the Danish GreenLab program.