Effective and efficient cleaning of metal bipolar plates

Low weight and volume, good cold-start capability and relatively inexpensive series production are all benefits associated with metal bipolar plates. These key elements in fuel cell stacks are responsible for handling the essential tasks of supplying media, creating an electrical connection and cooling. Their ability to perform these well depends on factors such as the cleanliness of both the material and the joined plate. Ecoclean has trialed a variety of processes to find the most effective and economical method of cleaning.

Fuel cells are among the key technologies for enabling the electrification of vehicle propulsion systems and also have a major part to play in the energy transition as a stationary energy source. At the heart of a fuel cell system are the bipolar plates or BPPs that are connected to the stacks. BPPs consist of an anode and a cathode with a proton-conducting film sandwiched between them.

BPPs fulfill a variety of tasks: They physically and electrically connect the anode of a cell to the cathode of the neighboring cell. They are also responsible for conveying the reactant gases – hydrogen on the anode side and air on the cathode side. For this purpose, the plates are designed with flow fields on both sides whose form is crucial for the performance of the overall system. In addition, the BPPs control the release of electrical energy and the removal of water vapor. Another function they perform is the management of heat.

Plates can be manufactured from different materials: high-concentration graphite, graphite-polymer composites and metals. Metal bipolar plates offer advantages particularly when it comes to their use in automobiles. This is because they are low in weight and volume and have a good cold-start capability. What’s more, metal BPPs offer the potential for comparatively cost-effective series production which can be further improved through scaling.

Clean for quality and efficiency

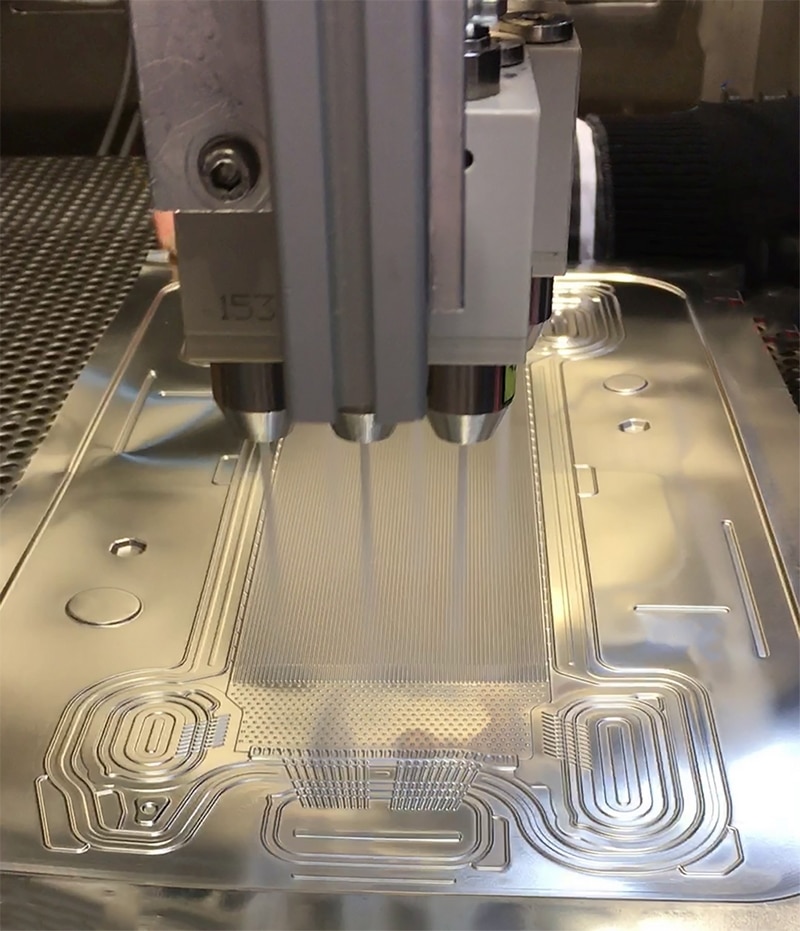

The anode and cathode of metal BPPs are predominantly made from stainless steel alloy foils with a thickness of 0.1 mm to 0.2 mm. The material is usually rolled off a coil whose surfaces are contaminated during manufacturing by different rolling and drawing greases, oils, emulsions and other unknown impurities. In the next step, the anode and cathode foils are precisely reshaped in a mechanical or hydroforming process and the outer contours are cut, for instance, by punching or laser cutting.

Residual machining fluids (oils and/or emulsions) are also left on the plates following these processes. When the anode plate and cathode plate are subsequently joined, commonly in a laser welding process, this results in smoke residue and oxide being left behind. Finally, the bipolar plates are coated. A cleaning stage must be performed prior to the plates being coated, if not earlier, to ensure a homogeneous coating with good adhesion.

For tightly packed fuel cells, which are required to achieve a high output in minimal space, it is recommended that cleaning takes place before the joining stage. This prevents impurities becoming trapped between the anode and cathode which can become loose when the temperature rises during operation and block the microstructures of the flow fields. This would lead to a decrease in performance. At the same time, the intermediate cleaning stage will reduce the surface contamination from smoke residue and oxides during the laser welding process.

Choosing the right process

A key challenge in cleaning metal BPPs is the presence of usually invisible chemical film residue on the surfaces. This may be oils, greases, emulsions or other chemicals that are often of unknown composition. These unidentified contaminants require a cleaning solution that ensures they are removed reliably and appropriately. This is why German company Ecoclean has carried out experiments using laser and carbon dioxide snow-jet cleaning, wet-chemical solvent cleaning as well as steam-jet cleaning.

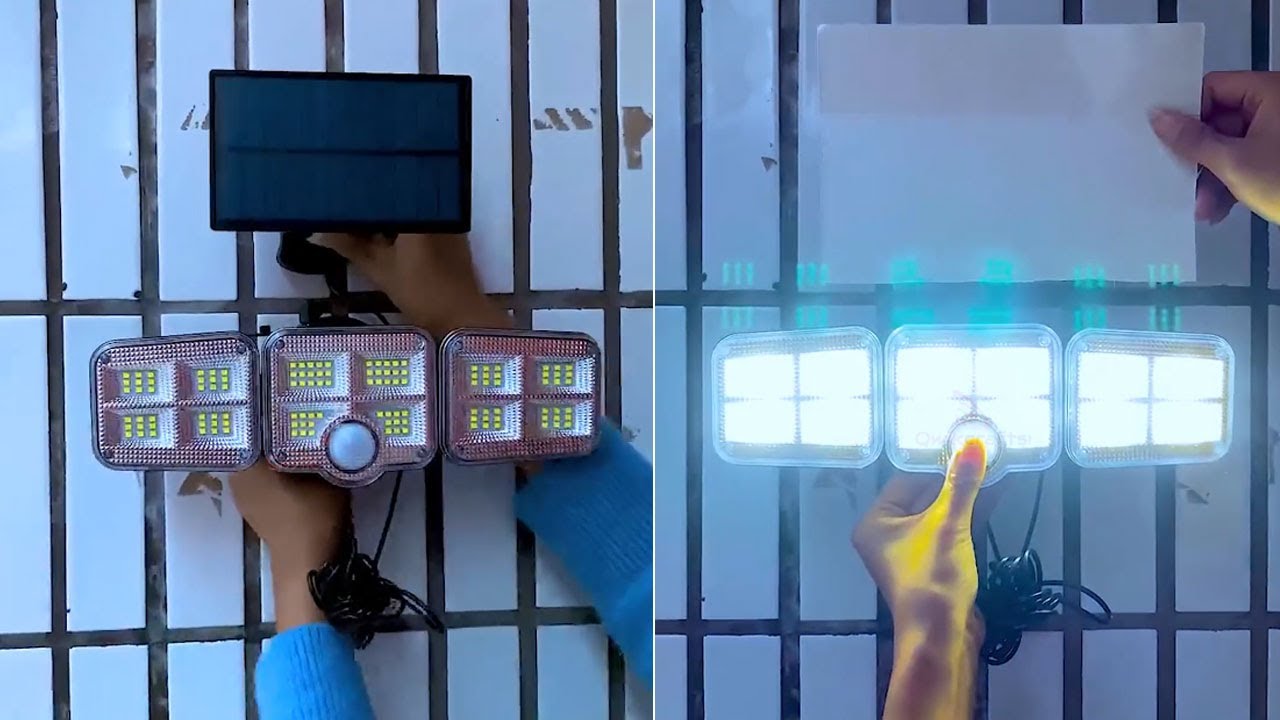

Fig. 2: Steam cleaning works due to a combination of steam, a precise quantity of fluid for the job, high-speed air flow and an adapted nozzle system

Both the laser and carbon dioxide snow-jet methods effectively removed smoke residue, oxide, chemical film contamination and particles from the welded seams of the joined bipolar plates with pin-point precision and within a matter of seconds. Good results were also recorded for both processes when cleaning whole BPP surfaces. Because the laser has to travel over the surface line by line, this option is time consuming. In the case of carbon dioxide snow-jet cleaning, the system can be fitted with an appropriate number of nozzles, thereby allowing for rapid treatment of the entire surface.

Wet-chemical cleaning with solvent using a flood method was able to successfully remove oils, greases and particles. However, it is not suitable for cleaning off emulsions, smoke residue and oxides. Wet-chemical immersion cleaning with water-based media is only possible to a limited degree due to the drying required and the considerable effort involved.

Good results were also achieved when using steam jets to clean chemical film and particulate contamination as well as smoke residue and oxides. For this process, the cleaning effect comes from a combination of steam, a precise quantity of fluid for the job, high-speed air flow and an adapted nozzle design. The cleaning procedure also takes just a few seconds.

Fig. 3: Analysis from infrared spectroscopy showed that steam cleaning completely removed the residue of the reference contamination

Controlled cleaning validation

Cleaning results are verified using the surface tension through the measuring techniques of contact angle measurement and test inks, fluorescence measurement and infrared spectroscopy. The fluorescence measuring technique proved to be unsuitable due to the absence of fluorescent contaminants. In terms of the input measurements for surface tension, the bipolar plates produced very different contamination values which were significantly reduced after cleaning.

A general statement about whether the component has a sufficient level of cleanliness for the next processing step cannot be made. For this to be possible, it would be necessary to determine appropriate process-specific requirements. For infrared spectroscopy, all residue on the test pieces (coil sections and BPPs) was first removed to establish a reference cleanliness. After the surfaces of the test pieces were analyzed using infrared spectroscopy, the test pieces were contaminated with reference contamination before being cleaned and then reanalyzed. This analysis then showed that steam cleaning managed to reliably remove chemical film contamination.

The cleaning trials and tests outlined were carried out in Ecoclean’s test center in Monschau by experts in component cleaning and surface treatment using the methods described as well as other techniques.

Automated cleaning

For an efficient workflow, it is possible for cleaning to be integrated prior to joining and/or coating in production lines. Automation can be adapted and optimized to suit the specific requirements and conditions of each production line.

Ecoclean is part of the SBS Ecoclean Group which develops, produces and distributes cutting-edge equipment, systems and services for industrial component cleaning and surface treatment. Its solutions help companies around the world from the automotive and supply industries as well as the highly diversified industrial market to implement efficient and sustainable production processes. The group has an international presence with 12 sites in nine countries and employs more than 900 staff.