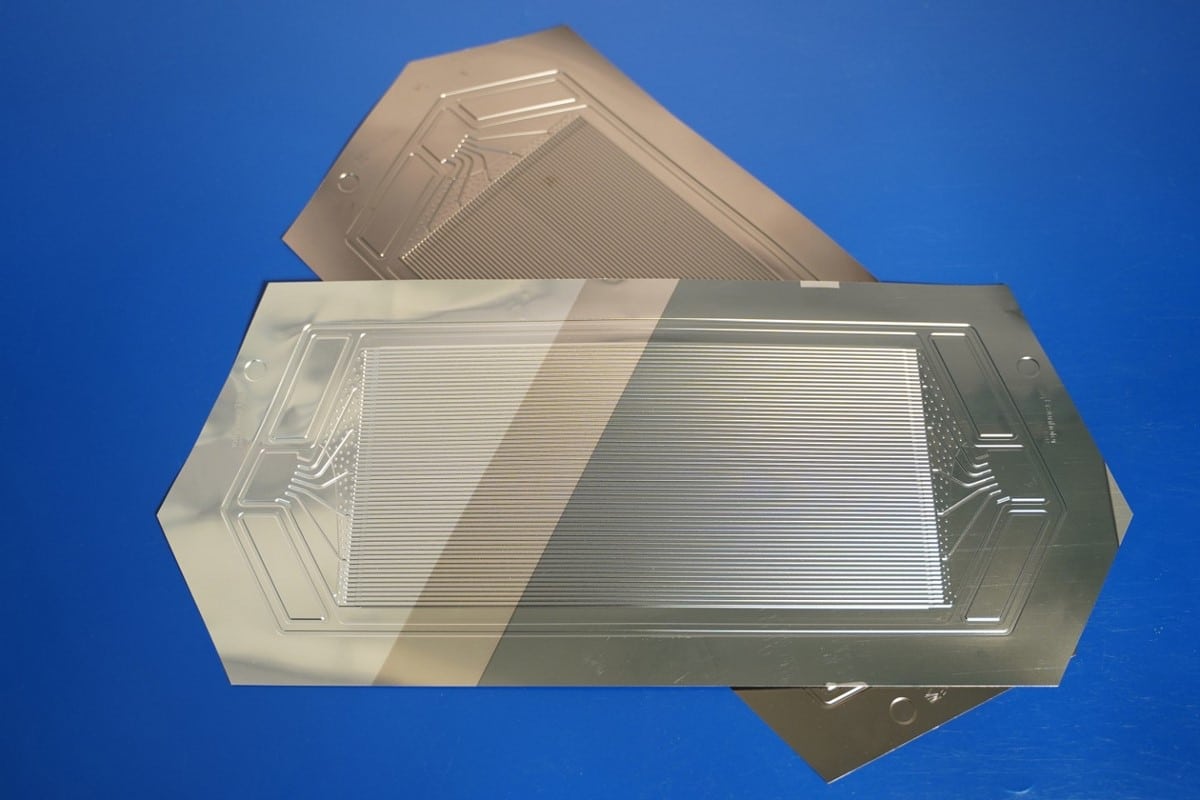

At Fraunhofer FEP (Fraunhofer-Institut für Organische Elektronik, Elektronenstrahl- und Plasmatechnik), a pilot plant for the coating of metal sheets and strips is being used for the efficient coating of bipolar plates for electrolyzers and fuel cells. The institute, according to its own statements, is a leader in the development of electron beam and plasma technologies. This expertise could also advance hydrogen technology in the future.

One example of this would be plasma-activated electron beam evaporation. This is a vacuum coating process that enables both high throughput and high coating quality. Exactly this combination is crucial for the coating of bipolar plates for electrolyzers and fuel cells. Because these have to function for a long time, stably, in a chemically aggressive environment. For this, they must receive coatings that reliably protect the plates and at the same time guarantee electrical conductivity.

Using electron beam evaporation, coatings to form a certain shape can be applied to the metal strip before these are stamped into bipolar plates, stated Burkhard Zimmermann, division manager for electron beam technologies at Fraunhofer FEP. The coating of the material is a crucial step for scaling the production with a roll-to-roll process. The challenge here is the formability of the coating. To ensure this, a dense macrostructure of the coating with the largest possible crystallites is required. Exactly these layer properties can be realized by the developed processes.