Obtaining hydrogen from vine shoots for biofuel production.

A research team from the universities of Jaén and São Paulo in Brazil has confirmed that hydrogen can be obtained from vine shoots through a process that does not require fossil fuels and does not emit pollutants. With their work, they manage to give new value to this waste from the wine industry, while creating environmentally friendly energy.

Almost 93% of the residues produced during the grape harvest are made up of debris, i.e., vine shoots, which until now have been used to produce organic compost or used as firewood. However, for some years now researchers have been looking for alternatives to take advantage of waste that could be very attractive for other industries such as pharmaceuticals or cosmetics, due to the high lignin content, from which compounds with antioxidant properties can be obtained.

In addition, biomass fermentation yields other products, such as hydrogen that is used as fuel, as described by these experts in the article “Vine shoots pre-treatment strategies for improved hydrogen production and metabolites redistribution in Clostridium butyricum,” published in the journal Industrial Crops and Products, where they confirm that biological pre-treatment of the shoots with an enzyme is the best option to start production on an industrial scale.

? What about we co-host a webinar? Let’s educate, captivate, and convert the biofuels economy!

Biofuels Central is the global go-to online magazine for the biofuel market, we can help you host impactful webinars that become a global reference on your topic and are an evergreen source of leads. Click here to request more details

Unlike other treatments that employ chemical or physical reagents, this process is more environmentally friendly, as it does not require recycling of waste products and does not release toxic compounds.

Juan Miguel Romero-García, one of the authors of the article said:

It also increases hydrogen production up to almost 250% compared to other pretreatment methods.

In this way, the experts open up new lines of study to generate clean energy from vine shoot biomass using a clean and sustainable method, a system that does not require chemical reagents that must be subsequently managed as waste, nor does it require high energy consumption in the process.

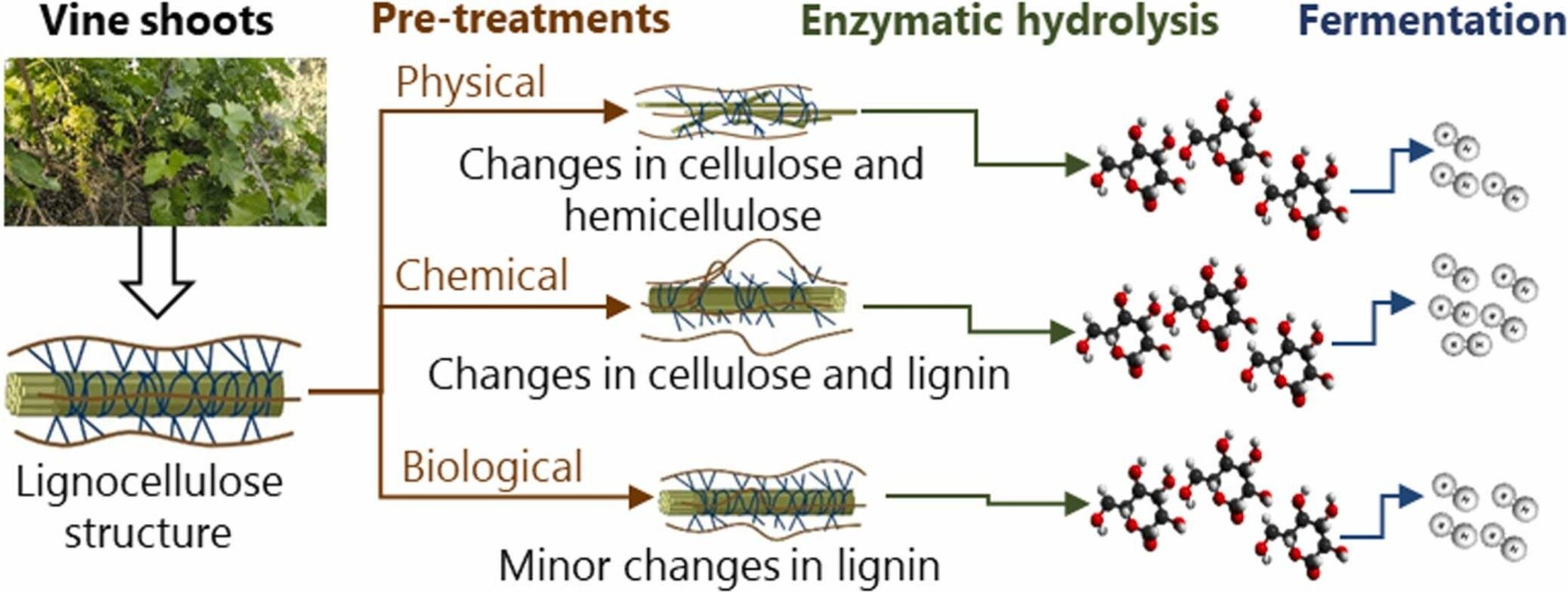

Chemistry and physics versus biology

The process for degrading vine shoots can be of different types. The physical method, on the one hand, involves the steam explosion of biomass, which requires high energy consumption. The chemical system, on the other hand, adds compounds such as ethanol, which can generate polluting residues.

Finally, the biological method introduces enzymes such as laccase, which separate the compounds. These procedures achieve the decomposition of the lignin and the alteration of the cellulose in the vegetable fiber, which causes the release of sugars.

Subsequently, a microorganism called Clostridium butyricum is introduced that ferments the mass obtained and produces organic acids, in addition to hydrogen, specifically butyric acid and acetic acid, both highly demanded by the food, cosmetics and pharmaceutical industries.

The experts compared the levels of hydrogen, lignin and these acids obtained with each of these methods and concluded that the system based on the biological process is the one that produces the most green fuel.

At the same time, they have also compared these results by applying enzymatic hydrolysis to break down the molecular structure and produce sugars prior to fermentation. In this case, the method that has shown the highest yield has been the one that subjected the vine shoot to a chemical treatment.

The researchers now propose to continue their studies to carry out a techno-economic and environmental evaluation of the process. The next step they intend to undertake is the analysis of the environmental impact of large-scale assembly of these facilities and the economic feasibility of developing a biorefinery based on vine branches.

READ the latest news shaping the biofuels market at Biofuels Central

Obtaining hydrogen from vine shoots for biofuel production, January 15, 2024